WILL YOUR WATER COIL DRAIN?

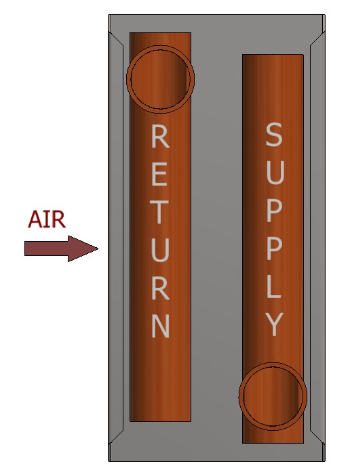

Water coils should have a vent at the high point and drain at the low point. Nortek coils are produced with either 1/8”, 1/2” or 3/4” vent and drain. These options make no difference if the coil is not built correctly.

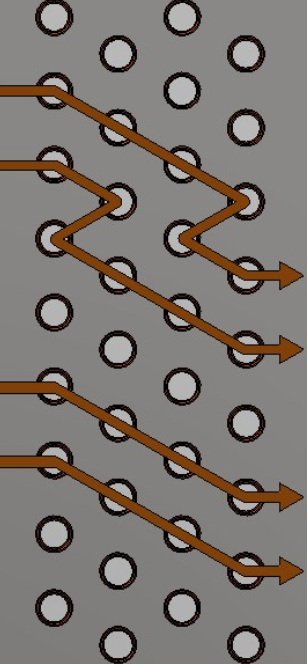

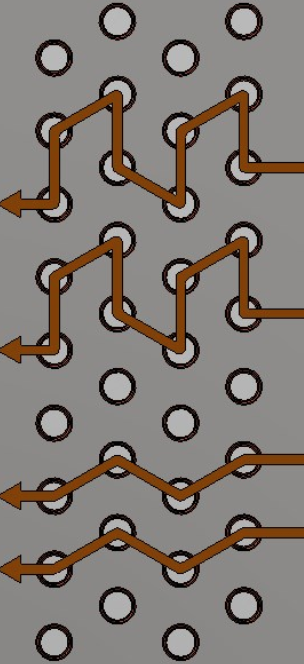

In this sketch are simple patterns to illustrate how return bends are placed to allow water to drain. You can see how the tubes are connected to provide level or downward water flow to the drain. This is not always the most straightforward method for manufacturing, but it must be done properly

There are always exceptions to every rule. We note these on our coil performance as follows: “Coil will not gravity drain for standard horizontal air flow position.” This exception is for very low water flow, requiring a low serpentine value. When you see this note, this is necessary to maintain the predicted coil capacity.

Lead Times

- Standard Production:

Orders are scheduled to ship by the fourth Friday after the released PO is received - Quick Ship:

2 workday production – add 100%*

(Contact factory to confirm material availability.)

5 workday production – add 50%*

10 workday production – add 25%*

*Minimum add per coil $100

Minimum PO amount $500

As a reminder, in the current state of the world, all manufacturers face supply chain challenges obtaining materials for production. The following are the current challenges we face in the coil market: